Direct-to-Metal Protection that Allows the Beauty of the Metal to Shine Through!

Permalac Thinners

See What Our Users Have to Say

“Permalac does a great job of sealing any number of components under the hood. It is especially effective in filling in and smoothing over the micro-pores that are always found on the surface of aluminum and other metals. After coating a newly finished alternator with Permalac, for example, the clean polished look will last for months, even years.”

“When I heard about Permalac I decided to try it. It lasts a lot longer than any other coating I’ve tried. Here in Nebraska, it can blow pretty hard, but I haven’t seen any evidence of coating failure.”

“The product was infallible. Permalac not only acts as a fungicide that resists mold, it positively repels it. Mold simply can’t and won’t grow on it.”

“Aside from protecting the carefully finished metal surface, Permalac has the advantage of being invisible. Unlike other lacquers it doesn’t give architectural coatings a plastic coated appearance and sheen.”

“Permalac is extremely easy to use, cures in about 2 hours, and can be sprayed vertically or horizontally without drip formation. Permalac just melts into itself, but even if a texture did develop, we just spray a little more Permalac and we obtain that smooth-as-glass finish our customers require.”

Application

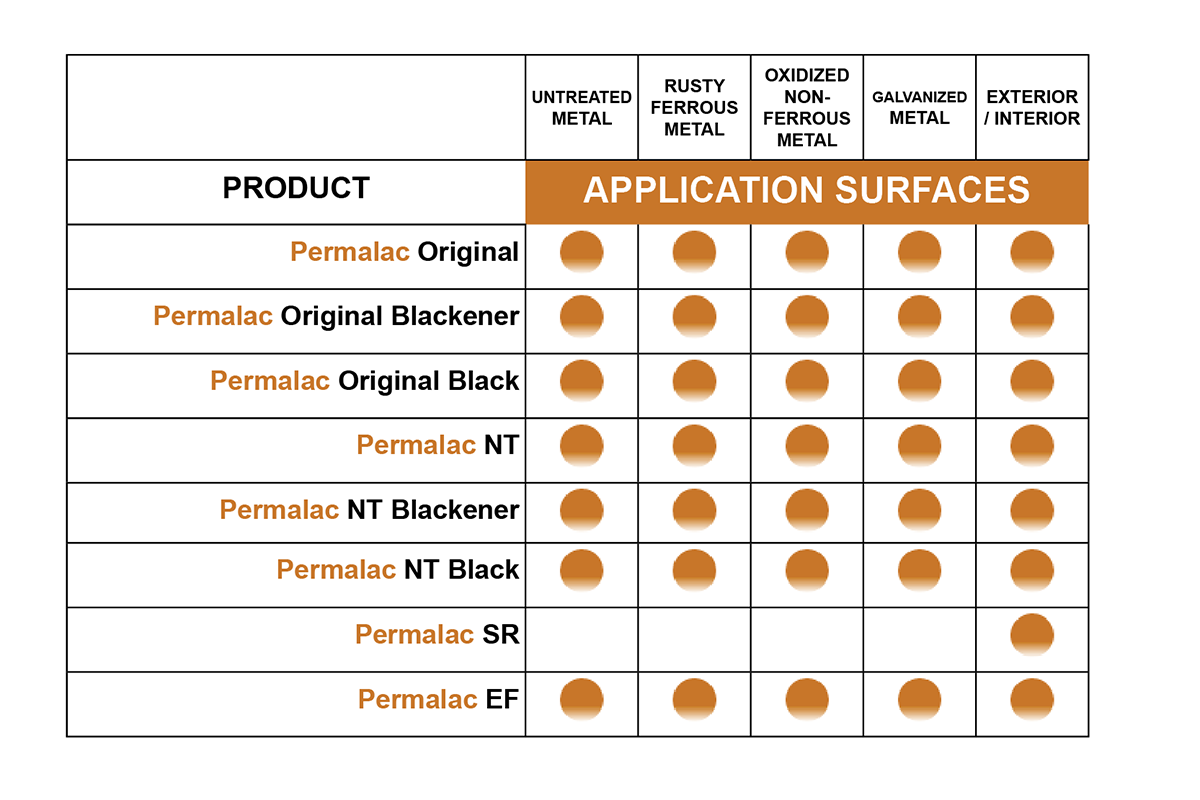

Permalac is an air-dry acrylic lacquer and direct-to-substrate protective coating for metal, stone, and wood. It’s primarily designed for protecting surfaces like bronze, brass, copper, steel, silver, and aluminum, and will work indoors or outdoors. Additionally, Permalac has been used in many other applications such as stone surfaces like masonry, stone monuments, terracotta, concrete surfaces such as floors, even antique interior wooden chairs. Painted or unpainted wood substrates are easily protected with Permalac as well. It can be applied via spray gun (HVLP or airless), brush, or dip method.

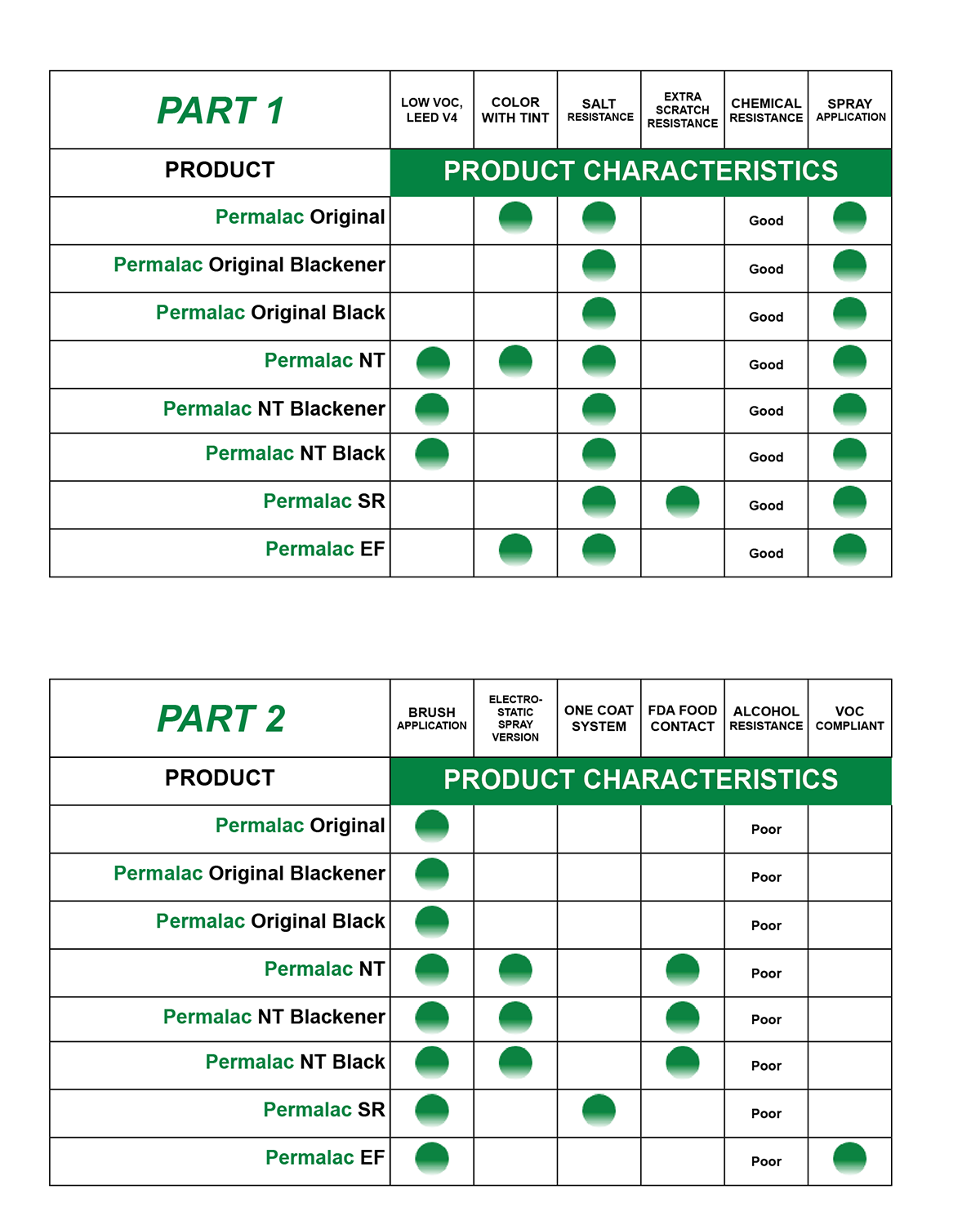

We formulated Permalac to be a superstar out in the field of application. It contains state-of-the-art UV and corrosion inhibitors, as well as wide-ranging temperature stabilizers, to assure endurance in the harshest conditions ranging from arctic freezing to desert heat, to beachfront salt air to acid rain. It can behave as both a sealer (in case you decide to paint over it) or as a highly resistant topcoat, providing protection from all types of environmental corrosives. On metals, Permalac is flexible and does not separate when the metal is bent. It also provides absolute protection for circuit breakers and other electrical components from molds and mildew, helping to avoid short-circuiting and other disruptive difficulties. Best of all, Permalac’s performance is long-lasting, meaning it can withstand anywhere from 3-5 years of corrosion in outdoor environments OR approximately 8-10 years of wear and tear indoors, all with a single application! This saves you time, money, and effort in the long run. Permalac is a premium product with exceptional performance and durability.